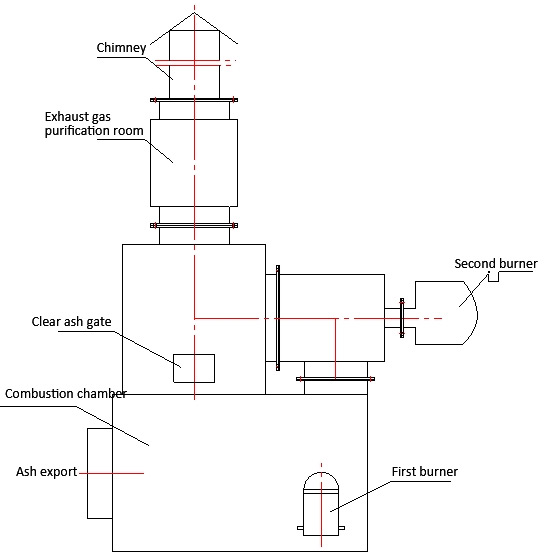

Oil-fired waste incinerator

Advantages of high temperature incinerator:

It uses fuel injection and a lot of air intake.

Oil-fired waste incinerator Advantages:

It can handle a large number of dead livestock and poultry, chemical liquids and other hazardous materials.

Disadvantages of high temperature incinerator:

The energy consumption is huge, the exhaust gas emissions are large, the service life of the furnace is short, and the operating capital after purchase is unaffordable for ordinary towns.

In high-temperature incinerators, the flame directly contacts the garbage to form combustion at about 600-1100 degrees Celsius, which is exothermic.

High temperatures easily vaporize metals in garbage. Part of the vaporized metal is discharged with the air, and part of it settles in the ash, causing excessive heavy metals.

The garbage is violently oxidized at high temperatures and with the support of the blast, a large amount of dust (with dioxin substances) is discharged from the chimney.

High temperature will inevitably produce high pressure. In fact, operators of high-temperature garbage incinerators need strict training and obtain a national-level furnace certificate before they can operate high-temperature incinerators.

Model project |

Daily processing capacity |

Incineration capacity |

200-300kg/bout |

Incinerator size/m |

2.2×1.4×3.8 |

Garbage inlet size(mm) |

900×1100 |

Induced draft fan |

Power 1.1kwh |

Combustion Support Burner(Estimated data) |

Power 0.22kwh |

Secondary burner |

Power 0.37kw |

Operating voltage |

380V / 220V |

Weight Approx.(kg) |

8000 |

Fuel consumption: 176-320m³ Diesel: 1m³( cubic meter) = 1000 liters |

|