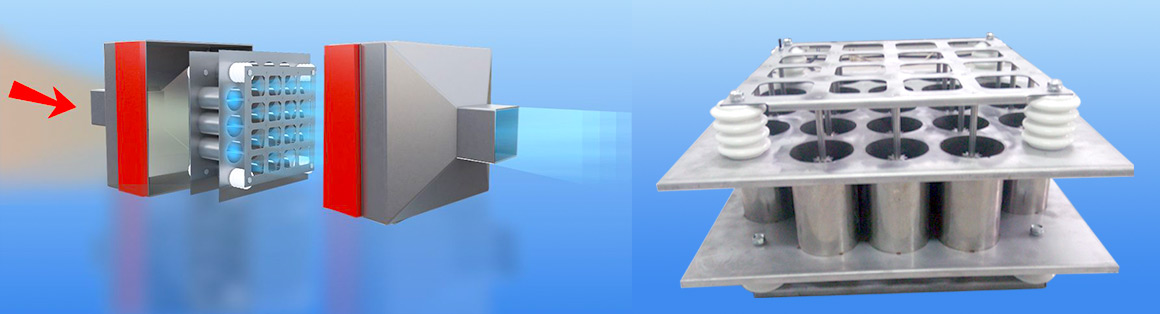

Low temperature plasma dust removal,deodorization and purification equipment

Low temperature plasma exhaust gas purification equipment, processing various gas pollutants process energy loss is very little, processing cost is low. High efficiency, is a very advanced pollutant treatment, environmental protection equipment.

Application of plasma equipment:

The application of plasma waste gas purification equipment is extensive. Used in petroleum chemical industry, pharmaceutical industry, feed and fertilizer processing factory, livestock farm products, the characteristic, tanneries, pulping plant, sewage pumping station, all kinds of sewage treatment plant, paint, food additive factory, leather processing, photographic materials, automobile manufacturing, and public toilets, waste transfer station, and many other industry organic waste gas, peculiar smell, the stench of pollution problems. It can also be used in indoor air purification.

Functions of low-temperature plasma exhaust gas purification equipment:

Low temperature plasma exhaust gas purification equipment under the action of external voltage, The primary electron gets accelerated in the electric field and hits the oxygen molecules in the air. When energy than oxygen ionization potential, oxygen molecules in a neutral molecules into negative oxygen ion (02 -), the result is oxygen adsorption of ionic polarization and neutral molecules to form 02 +, 02 -, 02, such as oxygen ion group gathered, with strong oxidizing, In a very short period of time, the harmful components of polluted air are oxidized into harmless products and water.

Performance parameters of low temperature plasma equipment:

- (1) Low temperature plasma treatment air volume: 2000m3/h---100000m3/h.

- (2) Purification efficiency of plasma organic waste gas: greater than or equal to 95%.

- (3) Wind resistance coefficient of low-temperature plasma device: 300pa.

- (4) Low temperature plasma power supply voltage: 220V/110V.50HZ

- (5) Low temperature plasma waste gas purification equipment has a voltage of 12,000 volts in the high voltage field.A power of 60 watts,We can have multiple combinations.

- (6) Equipment noise: 45DP.

Low temperature plasma treatment range:

Plasma exhaust gas purifiers eliminate and purify sulfur compounds such as hydrogen sulfide, mercaptan, dimethyl sulfide, sulfide and sulfur-containing heterocyclic compounds;

Plasma exhaust gas purifiers eliminate and purify nitrogenous compounds such as ammonia, amine, cyanogen and nitro compounds;

Elimination and purification of benzene series by plasma waste gas purification equipment: Such as styrene, benzene, toluene, xylene, etc. Contains halogen compounds, such as freon, chloroform, carbon tetrachloride, dichloromethane, etc.

Low temperature plasma waste gas purification equipment elimination and purification of lipids: Such as methyl acetate, ethyl acetate, butyl acetate, methyl acrylate, ethyl acrylate, butyl acrylate, etc.

Eliminate and purify the supersaturated and odorous moisture caused by cooking and fermentation, and the main application fields of low-temperature plasma: monosodium glutamate, pharmaceutical chemical industry, sludge drying and other industries.

Relatively closed and breathless room gas is treated by plasma purification, which produces high quality air containing negative ions.

For the eight malodorous substances specified in the national standard for odor control, Hydrogen sulfide, ammonia, trimethylamine, methyl mercaptan, methyl sulfide, carbon disulfide, styrene, dimethyl disulfide can be effectively removed.

Functional characteristics of low temperature plasma exhaust gas purification equipment.

- (1). Dust removal, sterilization, odor removal, degradation of organic waste gas, and release of negative ions.

- (2).Low energy consumption, high efficiency, low wind resistance, low noise.

- (3). The low temperature plasma waste gas treatment machine is made of stainless steel and has strong oxidation resistance and corrosion resistance in acid gas. The service life is more than 10 years.

- (4). The combination of plasma deodorizing equipment is strong: drawer-type design, simple installation, interconnection and parallel mixing application, which can play a significant advantage when dealing with high concentration odor gas.

Installation of plasma dust cleaning equipment:

- (1). The plasma purification equipment is installed in front of the fan and is recommended to be mounted on the bracket. Should be closely linked with the bracket.

- (2). The connection between the plasma waste gas treatment equipment and the exhaust pipe must be sealed.

- (3). Installation of low temperature plasma dust removal equipment to ensure maintenance space.

- (4). During the installation of the plasma exhaust gas dedusting equipment, foreign objects are forbidden to fall into the high-voltage field.

- (5).The connection of each line in the control box of plasma waste gas treatment equipment should be reliable.

- (6). The plasma purification equipment is connected to ac 220V/110V. The sound of continuous steady work.

Instructions for use of plasma exhaust gas purification equipment:

It is strictly prohibited to install plasma treatment equipment in the vicinity of excessive explosive gas and inflammable goods.

Suggestion: it must be installed by professional power engineers. If there is any problem, please communicate with our company in time.

The company is not liable for improper operation.

Fault solution of plasma exhaust gas purification equipment:

- (1). After power supply is turned off, maintenance is maintained.

- (2). When I turn on the power,Hear the relay patter,The voltage is out of range. Please turn the potentiometer count

- (3). Hear the sound of water flowing in the high piezo-electric field,It's the normal sound of the plasma. erclockwise to reduce the voltage.

- (4). The automatic power failure of the equipment may be caused by dust mist entering the equipment, resulting in an increase of equipment load. Please turn off the power to clean the electric field.

- (5). Cleaning method: clean with a brush, can not be treated, please use alkaline water to immerse the electric field for more than half an hour, the high-pressure water gun rinses.

- (6). Please check whether the inlet filter plate is dust saturated and replace the saturated filter plate regularly.

- (7). At this time, the plasma dust removal equipment cannot work properly, please contact our professional maintenance personnel for maintenance.

Matters needing attention of plasma waste gas purification equipment:

The side is the inlet direction, and the exhaust gas temperature is controlled at 1~70 degrees. Low-temperature plasma exhaust gas purification equipment installed in front of the blower, plasma exhaust gas purification equipment front-end should have spray water degradation of organic waste gas of large particles, in order to guarantee the equipment high voltage electric field inside clean, extend service time.

Maintenance of electrical system for low temperature plasma dedusting equipment:

- (1). After power supply is turned off, maintenance is maintained.

- (2). Clean up the dirt in the electrical cabinet.

- (3). Check the power module, find the problem and replace it in time.

- (4). Fastening terminals and power supply module wire screws.

Low temperature dedusting,deodorizing equipment safety,operation,maintenance and attention:

- (1). After power supply is turned off, maintenance is maintained.

- (2). The user shall designate a special person to carry out the maintenance of the product, and the maintenance shall be carried out according to the company's instructions;

- (3). The company accepts user's entrustment, is responsible for the regular maintenance and maintenance service of the product according to the contract.